Stock problems do not wait- they hit fast and drain profits before anyone notices.

A large number of companies across Australia struggle with stock shortages, slow order cycles, inaccurate counts and rising holding costs. These issues often build pressure inside operations, affect staff, delay customer orders and restrict monthly cash flow.

In many cases, teams have reported that fulfilment delays increased by nearly 28 percent and return-related losses climbed far beyond what they expected. It can hold back growth, impact long term trust and drain time that should be spent on planning.

So, this blog will take you through how AI in inventory management, smarter forecasting, practical tools and structured processes can cut these problems at the root.

You will also see how automation inventory management and guidance from the best AI development company have helped various businesses hit stronger accuracy, faster movement and better yearly outcomes.

Let’s Begin

AI for Inventory Management- A Quick Overview

AI in inventory management uses machine learning, predictive analytics, and data analysis to automate stock control, forecast demand, and optimise supply chains.

It examines historical sales data, market trends, and real-time information to ensure accurate replenishment, thereby reducing issues like overstock, stockouts, and holding costs.

Businesses can achieve real-time visibility across their warehouses through the integration of IoT and AI algorithms, which enhances efficiency, accuracy, and profitability.

Some notable examples include Amazon’s Kiva robots and Walmart’s inventory systems. Future trends are likely to focus on robotics and proactive risk management.

How Big is the AI Market in Australia?

According to a report: –

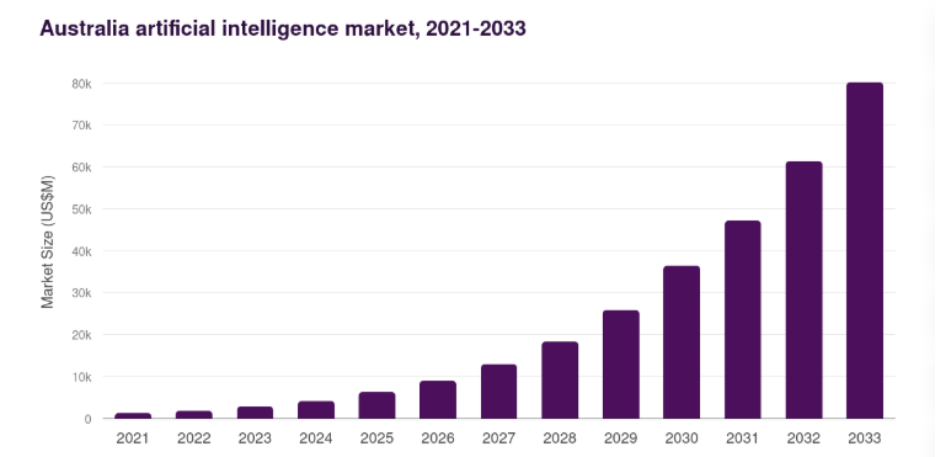

- The artificial intelligence market in Australia generated revenues of USD 4,197.0 million in 2024 and is projected to reach USD 80,150.5 million by 2033.

- The market is expected to grow at a compound annual growth rate (CAGR) of 37.7% from 2025 to 2033.

- In terms of segments, services represented the largest revenue-generating solution in 2024.

- Also, the services segment is anticipated to be the most profitable, showing the fastest growth during the forecast period.

AI in Inventory Management is Suitable For Which Businesses?

AI in inventory management is beneficial for almost all Australian businesses that hold stock. However, ai inventory management offers particularly transformative advantages for sectors with complex supply chains, high-value inventory, or perishable goods.

The artificial intelligence inventory management applications range from large enterprises to ambitious small and medium-sized enterprises (SMEs).

Retail & E-commerce

AI helps manage vast SKU (Stock Keeping Unit) counts, predicts seasonal demand, and optimises stock across both online and physical stores.

Wholesale & Distribution

It enhances forecasting accuracy and warehouse efficiency for businesses that move goods between manufacturers and retailers.

Manufacturing

AI optimises raw material procurement, manages work-in-progress inventory, and predicts maintenance needs for MRO (Maintenance, Repair, Operations) stock.

Agriculture & Horticulture

AI is crucial for managing perishable produce, predicting yields, and optimising storage to reduce waste.

Healthcare & Pharmaceuticals

It ensures compliance with regulations, manages sensitive product expiry dates, and prevents critical stockouts of essential supplies.

Food & Beverage (Hospitality)

AI predicts ingredient demand, reduces spoilage, and manages inventory across franchise or multi-venue operations.

Mining, Construction & Industrial

It tracks high-value equipment and spare parts, predicting needs for remote sites to minimise costly downtime.

Logistics & Transport

AI optimises fleet loading and warehouse space utilisation within the supply chain.

What is the Need for AI Inventory Management for Businesses?

AI in inventory management is essential for addressing the complexities of modern supply chains and the data-driven demands that traditional systems struggle to handle.

Implementing AI for inventory management is essential for survival and competitiveness in modern volatile global market.

Global Supply Chain Volatility

Unpredictable international logistics, geopolitical issues, and the lingering effects of the pandemic have rendered traditional forecasting methods ineffective.

Rising Consumer Expectations

The demand for fast, omnichannel fulfillment (such as buy online, pick up in-store) creates complex challenges for inventory allocation.

Overwhelming Data Volumes

Businesses generate vast amounts of data from sales, suppliers, and IoT sensors, making it impossible to manually analyse for optimal stock levels.

Inaccurate Demand Forecasting

Traditional forecasting models struggle with volatile demand patterns, resulting in frequent stockouts or overstocking of seasonal or trending products.

High Operational Costs

Inefficient manual processes and suboptimal stock placement lead to increased expenses in warehousing, labour, and capital tied up in unsold goods.

Multi-Channel Inventory Silos

Managing separate inventories for online, retail, and wholesale channels creates visibility gaps and missed transfer opportunities.

Supplier Reliability Issues

Fluctuating lead times and inconsistent reliability from overseas suppliers necessitate dynamic and automated adjustments to replenishment strategies.

Competitive Pressure

Competitors using AI for leaner operations and improved service levels create a technological imperative to keep pace.

Key Benefits of AI for Inventory Management

AI is transforming inventory management by delivering exceptional accuracy, efficiency, and predictive capabilities. For Australian businesses, it leads to significant cost savings, enhanced customer satisfaction, and a strong competitive advantage in both local and global markets.

Some of the key benefits of inventory optimisation include: –

1. Better Demand Forecasting

AI analyses local sales data, seasonal trends, and events (such as the AFL finals) to accurately predict demand, helping to prevent stockouts and overstock situations.

2. Optimised Stock Levels

AI automatically calculates ideal reorder points and safety stock levels, minimising the capital tied up in excess inventory.

3. Reduced Operational Costs

Implementing AI by partnering with a AI development company will lower costs associated with warehousing, waste, and manual stocktaking, which ultimately improves profit margins.

4. Minimised Stockouts and Overstock

AI helps maintain a delicate balance between having too little and too much stock, ensuring customer satisfaction.

5. Improved Supply Chain Resilience

AI can identify potential disruptions in both global and domestic logistics, allowing businesses to proactively plan for contingencies.

6. Automated Warehouse Operations

AI powers robotics and vision systems for faster and more accurate picking, packing, and stocktaking processes.

7. Real-Time Visibility

AI provides a single, accurate view of inventory across all locations and sales channels, which is crucial for multi-channel retailers.

8. Dynamic Pricing Optimisation

AI adjusts pricing in real-time based on stock levels, demand, and competitor pricing to help clear excess inventory or maximise profits.

9. Data-Driven Purchasing Decisions

AI analyses supplier performance, lead times, and quality to inform smarter, automated purchasing decisions.

10. Reduced Manual Labor and Errors

By automating tedious data entry and inventory counts, AI frees up staff for more valuable tasks while improving data accuracy.

11. Sustainability Improvements

AI helps reduce waste (particularly for perishable goods) and optimises transportation, supporting environmental goals.

12. Scalability

AI easily scales operations to handle peak periods, such as Christmas or Black Friday, without a proportional increase in management complexity.

Artificial Intelligence Inventory Management- Key Strategies For Business

Australian businesses can improve their inventory management by implementing strategies and AI inventory management tools that cater to local market dynamics and challenges.

1. AI-Powered Demand Sensing for Sparse Geographies

The use of ai in inventory management system will help analyse localised data such as regional events, weather patterns, and transport delays to optimise stock levels in areas with dispersed populations.

Such an approach helps reduce both overstocking and stockouts in isolated regions.

2. Supply Chain Resilience Modelling

With AI in inventory management, you can simulate potential disruptions caused by climate events, port delays, and global shortages.

It allows for the creation of dynamic contingency plans for critical inventory.

3. Cross-Channel Fulfillment Optimisation

Use AI algorithms to intelligently route online orders from the most efficient stock location whether it be a store, warehouse, or supplier. Such strategy reduces domestic shipping times and costs.

4. Ethical and Sustainable Stock Intelligence

Leverage AI to prioritise inventory from ethical suppliers and to optimise for carbon footprint.

This approach aligns with increasing consumer demand and regulatory pressures for sustainability.

5. Automated Customs and Compliance Forecasting

Integrate AI to anticipate customs clearance times and automatically update tariff codes.

It simplifies the complex import/export documentation process.

6. Seasonal and Promotional Agility

Use AI to model the impact of Australia’s unique seasonal patterns and local promotional events (such as Click Frenzy) on specific product demand.

7. Supplier Performance Analytics

Employ AI to continuously assess supplier reliability, pricing, and lead times. This allows businesses to make dynamic adjustments in sourcing.

8. Predictive Maintenance for Onshore Assets

Use AI to analyse IoT data from automated warehouses and machinery.

Such a pre-emptive approach helps identify potential failures, ensuring uninterrupted local operations.

9. AI-Driven Markdown Optimisation

Apply machine learning to strategically mark down seasonal or perishable goods, maximising revenue from slow-moving inventory.

10. Unified Data Lake Integration

Create a centralised AI platform that ingests data from point-of-sale systems, suppliers, logistics, and even social media.

It generates a single, accurate view of inventory.

7 Successful Examples of Businesses Using AI in Inventory Management

Australian businesses are using artificial intelligence (AI) to optimise stock levels, predict demand, and automate replenishment, leading to significant improvements in efficiency and cost reductions.

AI inventory management technology is becoming a key competitive advantage for various companies, from major retailers to innovative suppliers.

Some famous businesses in Australia who invested in ai inventory management system are: –

1. Woolworths

The supermarket chain employs AI demand forecasting to optimise inventory across its extensive network, reducing waste and improving product availability.

2. Kogan.com

The online marketplace uses AI algorithms to automate inventory purchasing and dynamically manage stock levels.

3. Afterpay (through ClearCo)

ClearCo, a subsidiary of Afterpay, uses AI to analyse sales data and offer inventory financing recommendations to retail partners.

4. Blackmores

The health supplements giant leverages AI for demand sensing and inventory planning, aligning production with market needs more effectively.

5. Officeworks

The office supply retailer implements AI and machine learning for predictive inventory management, ensuring optimal stock levels both online and in-store.

6. Endeavour Group (BWS, Dan Murphy’s)

Endeavour Group applies AI to forecast demand for thousands of products, optimise stock across its liquor retail chains.

7. SEA Logistics Group

The logistics provider uses AI to offer clients real-time visibility and predictive analytics for inventory in transit and warehousing.

Must Read – Real World AI Development Use Cases Across 10+ Different Industries

The Future of AI in Inventory Management

The future of AI in inventory management in Australia is characterised by significant advancements in machine learning and automation that are transforming traditional inventory processes.

AI-powered platforms facilitate accurate demand forecasting, provide optimal stock level recommendations, and enable early identification of potential supply issues.

As a result, there is a reduction in manual labour, fewer stockouts, and minimised excess inventory, which ultimately enhances profitability and customer satisfaction.

Australian retailers benefit from real-time inventory visibility and improved decision-making through AI integration with sales and supply chain systems.

Overall, the adoption of AI promises greater efficiency, precise stock control, and a competitive advantage in the evolving retail landscape of Australia.

Scale Your Business By Developing a Reliable Inventory Management Software

When you reach the point where manual checks, scattered spreadsheets, slow updates and rising stock errors keep blocking growth, the next step becomes clear.

A structured system with AI inventory management software can bring accuracy, control, steady movement and clearer forecasting to your daily flow.

With 15+ years of experience, 500+ successful deployments and 200+ clients, Vrinsoft Pty Ltd has helped companies replace guesswork with practical results.

Teams that adopted focused automation saw fulfilment delays drop by more than 31 percent and month-end reconciliation time fall sharply.

If you want to work with a leading AI development agency that understands real business pressures, our team will guide you with AI development solutions built to handle complex stock activity, multi-location operations and growth planning.

Check our portfolio and see how AI development in Australia is supporting better outcomes for companies that need a stronger path forward.

Contact us or simply call at 0480027297 to begin your FREE conversation with our experts.